Table of Contents

Advanced Technology Behind the Agricultural Robotic Gasoline Electric Traction Travel Motor Crawler

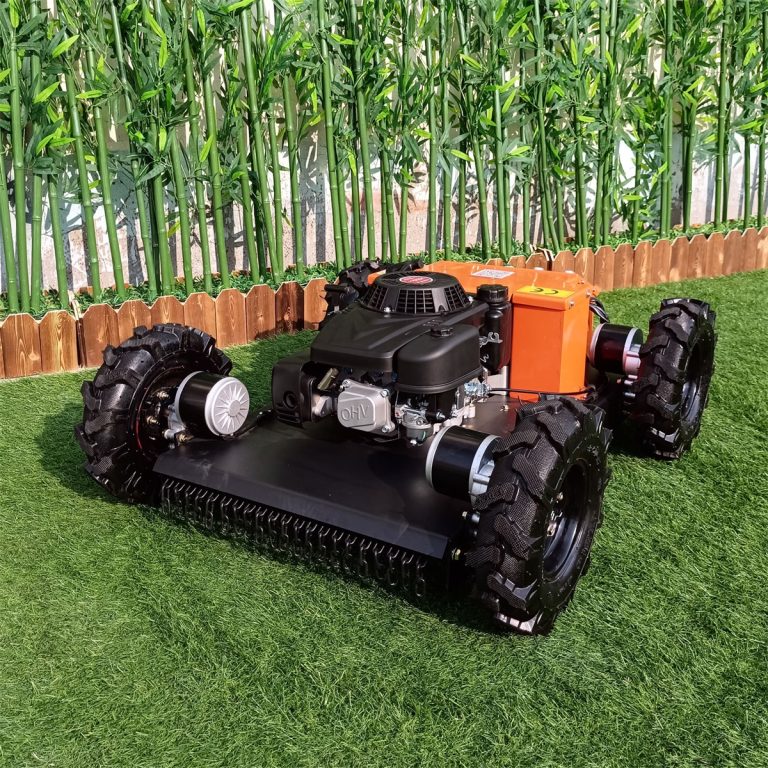

The agricultural robotic gasoline electric traction travel motor crawler remotely controlled forestry mulcher is a remarkable innovation designed for efficiency and versatility in various outdoor tasks. This machine is powered by a V-type twin-cylinder gasoline engine, specifically the Loncin brand model LC2V80FD. With a rated power of 18 kW at 3600 rpm, this 764cc engine ensures robust performance, making it suitable for challenging environments. One of the standout features of this machine is its clutch system, which only engages when the engine reaches a predetermined rotation speed. This design enhances the operational control of the crawler, allowing for smooth transitions during tasks. Operators can rely on the machine to deliver consistent power without unexpected interruptions, ensuring that each job is completed efficiently. Additionally, the machine is equipped with two powerful 48V 1500W servo motors that provide excellent climbing capability. The built-in self-locking function guarantees that the machine remains stationary unless both power is applied and throttle input is given. This safety feature significantly reduces the risks of unintended movement, making it safer for operators working on slopes or uneven terrain.

Versatile Applications and Enhanced Safety Features

The agricultural robotic gasoline electric traction travel motor crawler remotely controlled forestry mulcher stands out not just for its power but also for its versatility. Its high reduction ratio worm gear reducer amplifies the already significant torque produced by the servo motors, delivering exceptional output torque for climbing resistance. This means that even on steep inclines, the machine performs reliably.

Moreover, in power-off situations, the friction between the worm and gear provides mechanical self-locking, preventing the machine from sliding downhill. This feature enhances safety, allowing operators to work with confidence, knowing that the machine will remain stable even in challenging conditions. The intelligent servo controller plays a crucial role in regulating motor speed and synchronizing movement, allowing for seamless operation.

The agricultural robotic gasoline electric traction travel motor crawler remotely controlled forestry mulcher stands out not just for its power but also for its versatility. Its high reduction ratio worm gear reducer amplifies the already significant torque produced by the servo motors, delivering exceptional output torque for climbing resistance. This means that even on steep inclines, the machine performs reliably.

Moreover, in power-off situations, the friction between the worm and gear provides mechanical self-locking, preventing the machine from sliding downhill. This feature enhances safety, allowing operators to work with confidence, knowing that the machine will remain stable even in challenging conditions. The intelligent servo controller plays a crucial role in regulating motor speed and synchronizing movement, allowing for seamless operation.

In comparison to many competing models that utilize 24V systems, this machine’s 48V power configuration results in lower current flow and heat generation. This leads to longer operational periods without overheating, ensuring that the machine can handle extended tasks such as slope mowing without performance degradation. The design prioritizes efficiency and safety, catering to the needs of professionals in demanding environments.

In comparison to many competing models that utilize 24V systems, this machine’s 48V power configuration results in lower current flow and heat generation. This leads to longer operational periods without overheating, ensuring that the machine can handle extended tasks such as slope mowing without performance degradation. The design prioritizes efficiency and safety, catering to the needs of professionals in demanding environments.